Polyurethane

Trymer® 2000, 6000, 25-50 & Accessories

Trymer® 2000XP

Trymer® 6000

Trymer® 25-50

Jacketing Options

Leading Manufacturer of Polyurethane Pipe Insulation

Thermal Fabrication has been a leading manufacturer of Polyisocyanurate (Urethane) products in New England for over three decades. We specialize in manufacturing pipe insulation systems for equipment operating below ambient temperatures, such as chilled water and refrigeration piping.

Low temperature mechanical insulation applications present special challenges due to the tendency of water vapor to move toward the cold pipe.

Urethane insulation systems are proven to be far superior to alternatives such as fiberglass, extruded polystyrene, or cellular glass. In addition, Polyisocyanurate’s water absorption and water vapor transmission properties are far better than fiberglass or XPS, and approach those of cell glass.

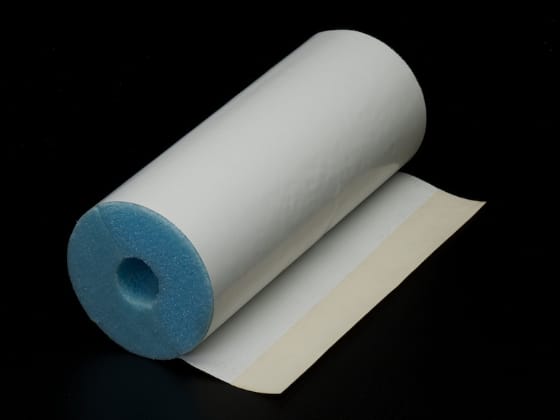

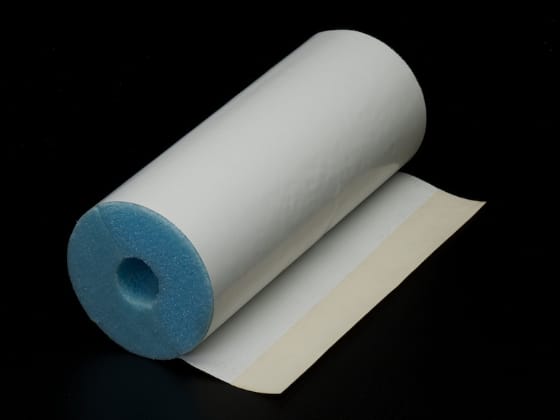

Trymer® 2000XP

Trymer® 2000XP is a closed-celled insulation that features improved dimensional stability over a wider range of temperatures than standard polyurethane insulation. It’s made of polyurethane modified polyisocyanurate (PIR) cellular plastic. Trymer insulation isn’t a known nutrient source for mold and mildew.

Shapes & Sizes: This rigid insulation is supplied in the form of bunstock for fabrication into sheets, pipe shells, tank and vessel overings, and other shapes for a variety of thermal insulation applications. We also fabricate 18” sections of Trymer® 2000XP (#2) and Trymer 6000 (6#) for areas that require support around pipe hangers/supports.

Applications: Trymer® 2000XP can be used within the service temperature range of -297°F to 300°F (-183°C to 149°C). It’s ideal for use as:

- Industrial pipe insulation (including elbows and fittings)

- Core material for architectural and structural panels

- Core material for factory built panelized constructions

- Insulation for shipping containers, trucks, or railcars

- Commercial chilled water insulation

- Tank and vessel insulation

- Flat or tapered board stock for roof insulation

Suitable for applications that require a Flame Spread Index of 25 or less and a Smoke Developed Index of 450 or less when tested as per ASTM E48 — these are typical requirements for pipe insulation located in non-plenum locations.

Trymer® 6000

Shapes & Sizes: We also fabricate 18” sections of half Trymer® 6000 (#6) and half Trymer 2000XP for areas that require support around pipe hangers/supports. In addition, we fabricate insulation saddle blocks with the Trymer® 6000.

Applications: Trymer® 6000 is used extensively in industrial and commercial applications with moderate density/strength requirements. It can be used within the service temperature range of -297°F to 300°F (-183°C to 149°C). Typical applications include:

- Fabricated pipe insulation, including elbows and fittings

- Core material for factory built panelized constructions

- Pipe hangers, saddles, and supports

- Core material for architectural and structural panels

- Tank and vessel insulation

Trymer® 25-50

Applications: Trymer® 25-50 meets the most stringent flame spread and smoke developed rating requirements in most building codes, making it ideal for insulating chilled water piping in commercial buildings. For pipe insulation up to 1.5” located inside plenums of commercial buildings, JM recommends the use of our Trymer® 25-50 insulation.

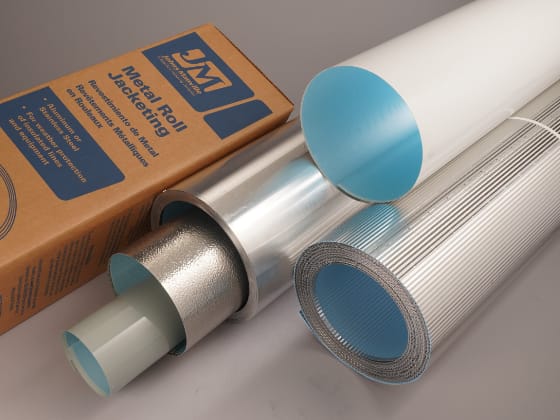

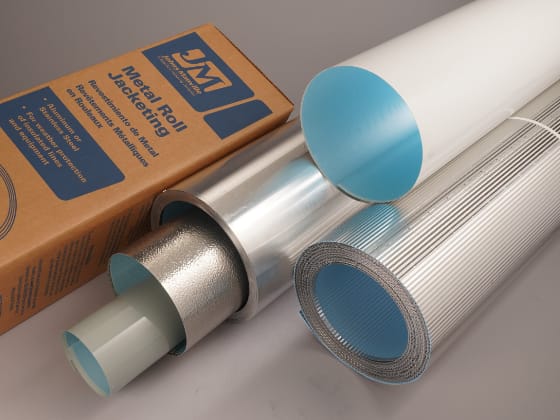

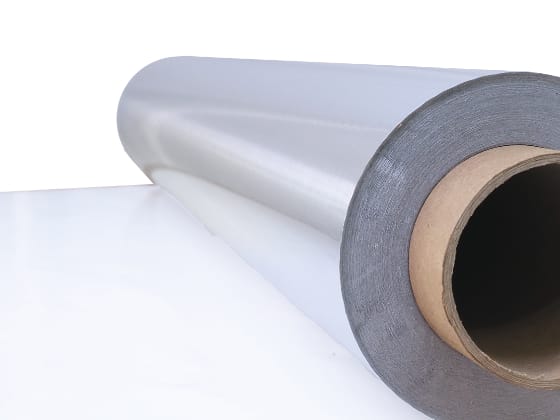

Jacketing Options

Thermal Fabrication supplies the following jacketing options:

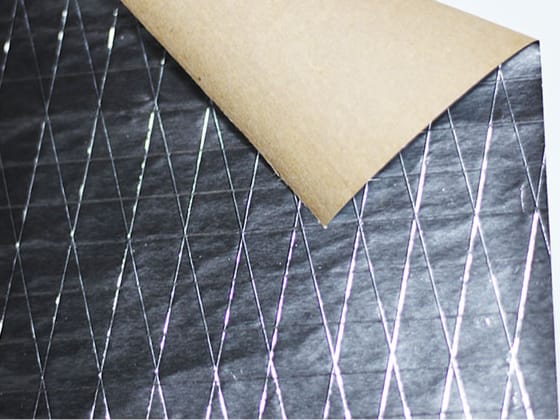

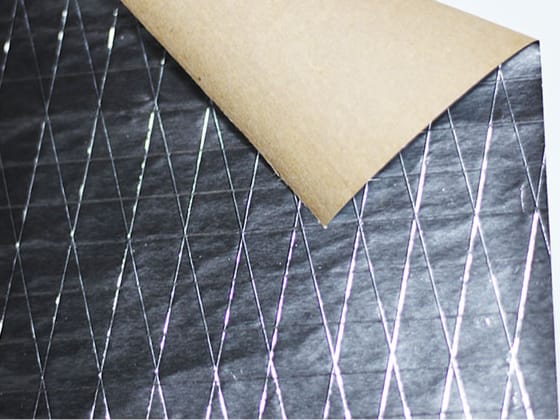

Polyguard Zero-Perm

Polyguard Insulrap-50 NG

LAMTEC Corporation–R-3035 Foil-Skim Kraft (FSK)

LAMTEC Corporation-All-Service Jacket (ASJ)

Proto PVC Jacketing & Fittings